The production of advanced lithium-ion cells involves a precise step: cell stacking. It delivers fundamentally for achieving high energy density and consistent performance in next-generation batteries used in electric vehicles, energy storage systems, and consumer electronics.

The market for battery cell stacking equipment reflects this growing importance. Valued at about USD 150 million in 2024, it is projected to reach USD 400 million by 2033, representing a strong compound annual growth rate (CAGR) of roughly 12.1% from 2026 to 2033. Such robust expansion underscores the pivotal role stacking technology plays in meeting surging global demand for efficient, high-capacity batteries.

Against this backdrop of rapid market growth and technological refinement, it becomes crucial to understand the specific factors that are propelling battery stacking technology to thrive—from manufacturing innovations to material advances and evolving application needs.

Definition: What is Battery Cell Stacking?

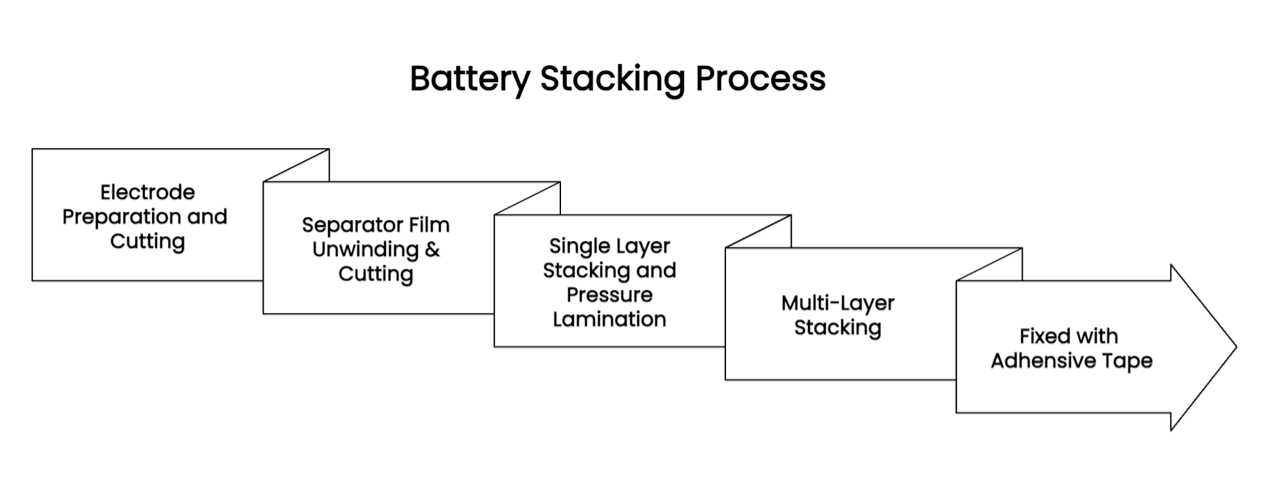

Building on its growing market significance, it helps to first clarify what battery stacking actually is and how it functions in modern cell production. Battery cell stacking (also known as cell lamination) involves layer-by-layer assembly of electrodes and separators, rather than rolling them up as in winding. The key steps generally are:

Because of this meticulous layering and improved internal structure, manufacturers gain several performance and production :

- Higher Energy Density: The flat stack reduces unused space, allowing more active material within the same footprint.

- Improved Thermal Management: Even contact between layers helps dissipate heat and maintain stable operating temperatures.

- Design Flexibility: Cells can be shaped to fit diverse electric vehicle and energy-storage applications

Development of Battery Cell Stacking: Why It Thrives?

As mentioned above, with a projected market value climbing to US$400 million by 2033, the battery cell stacking sector is on a strong upward path. This sustained momentum is not coincidental; rather, it reflects a convergence of market trends, including the need for efficient renewable energy storage, demand for larger high-performance cells, and supportive government policies.

Rising Demand for Efficient, Sustainable Energy Storage

The global emphasis on cleaner energy sources, such as solar and wind, requires large-scale, dependable storage systems to balance intermittent supply. The stacked-cell technique offers high energy density and long cycle life, making it essential for integrating renewables into the grid, and thus making stacking equipment an attractive investment for energy providers.

Need for Larger, Higher-Performance Cells

Automakers and utility-scale storage developers are seeking bigger battery formats with greater capacity and stable thermal behavior. Stacking enables cells with consistent internal alignment, supporting higher capacities and improved safety—qualities that conventional winding struggles to match at scale.

Accelerating Electrification and Policy Incentives

From electric transportation to residential storage, electrification is on the rise. Government initiatives in the European Union, the United States, and other regions, ranging from tax credits to manufacturing subsidies, are encouraging rapid expansion of advanced battery production lines, directly boosting demand for sophisticated stacking machinery.

LEAD: Meeting Growing Cell Stacking Demands

As the battery industry grows, manufacturers require equipment that combines speed, precision, and reliability to meet higher production standards. LEAD’s 390 High-Speed Cutting and Stacking Machine is designed precisely for this purpose, integrating multiple functions into a seamless process.

All-in-One Integration: The machine combines electrode unwinding, cutting, stacking, taping, and unloading in a single workflow. This integration reduces handling errors, saves time, and ensures consistent alignment throughout the production cycle.

Optimized Stack Dimensions: The “390” designation highlights the machine’s ability to handle stack heights of 390 mm, up to 400 mm, within a working range of 80–240 mm (W), 80–400 mm (H), and 4–35 mm (T)—ideal for diverse cell formats.

Contamination Prevention: The stacking transfer belt is fully sealed, protecting electrodes from dust and impurities, which helps maintain battery quality and reliability.

Intelligent Commissioning: Advanced software enables one-key commissioning and reset, power-on self-test, and intelligent adjustment. The system also supports preventive maintenance, minimizing downtime and ensuring smoother production lines.

Precision Tension Control: A two-stage adaptive control keeps separator tension within 5% during stable stacking, with peaks limited to 12%, ensuring uniform stacking pressure and reducing the risk of defects.

By combining these features, LEAD’s Cutting and Stacking Machine addresses the growing demand for high-capacity, high-performance batteries while supporting scalable, efficient, and reliable manufacturing.

Challenges Ahead for the Battery Cell Stacking Market

While the battery stacking sector is growing rapidly, the market also faces several significant challenges that manufacturers and equipment providers must navigate.

Fluctuating Battery Raw Material Prices

Key battery components, such as lithium and cobalt, are subject to global price volatility. Sudden increases can significantly raise production costs and affect profit margins, creating uncertainty for manufacturers planning large-scale expansion.

High Initial Investment in Equipment

Advanced stacking machines require substantial capital investment, which can limit smaller or mid-sized companies from scaling operations quickly. Despite the strong market potential, this barrier slows wider adoption of high-precision automation in battery production.

Complexity and Quality Challenges in Stacking

The stacking process itself is intricate and demanding. Even minor inconsistencies—such as uneven edges or burrs—can reduce the performance and lifespan of the final battery. Achieving a high electrode yield is challenging, yet this underscores the importance of precision equipment like LEAD’s 390 Cutting and Stacking Machine. It maintains tight control over separator tension and alignment, ensuring consistent quality and higher yields.

Reference

- https://www.verifiedmarketreports.com/zh/product/battery-stacking-machine-market/

- https://www.pem.rwth-aachen.de/global/show_document.asp?id=aaaaaaaaabdqbtk

- https://www.grepow.com/blog/cell-stacking-definition-grepow-battery-technology.html

- https://beyond-battery.com/blogs/beyond-battery-blogs/why-stacking-is-overtaking-winding-for-high-rate-batteries

- https://www.tobmachine.com/blog/comparative-analysis-of-stacking-vs-winding-processes-in-lithium-battery-manufacturing_b129