In an increasingly competitive manufacturing landscape, intelligent logistics has evolved from a traditional “back-end support” function into a core driver of enterprise competitiveness.

As a subsidiary of Lead Intelligent Equipment, Lead Logistics has spent years deeply engaged in the logistics systems of the new energy and advanced manufacturing industries. Drawing on extensive technical expertise and practical experience, Lead Logistics has joined hands with leading intelligent equipment manufacturers to develop a Smart Manufacturing Logistics Center — a flexible and adaptive solution that revitalizes the “logistical lifeline” of high-end manufacturing and sets a new rhythm of operational efficiency.

High-Complexity Scenarios, High-Performance Demands

With rapid business expansion and the surge in SKU volume, traditional warehouse systems are under growing strain. The requirements for 100% kitting rate and high-throughput transport expose the limitations of manual or semi-automated operations, often leading to warehouse congestion, delayed scheduling, and reduced responsiveness.

Intelligent Transformation of Manufacturing Warehousing

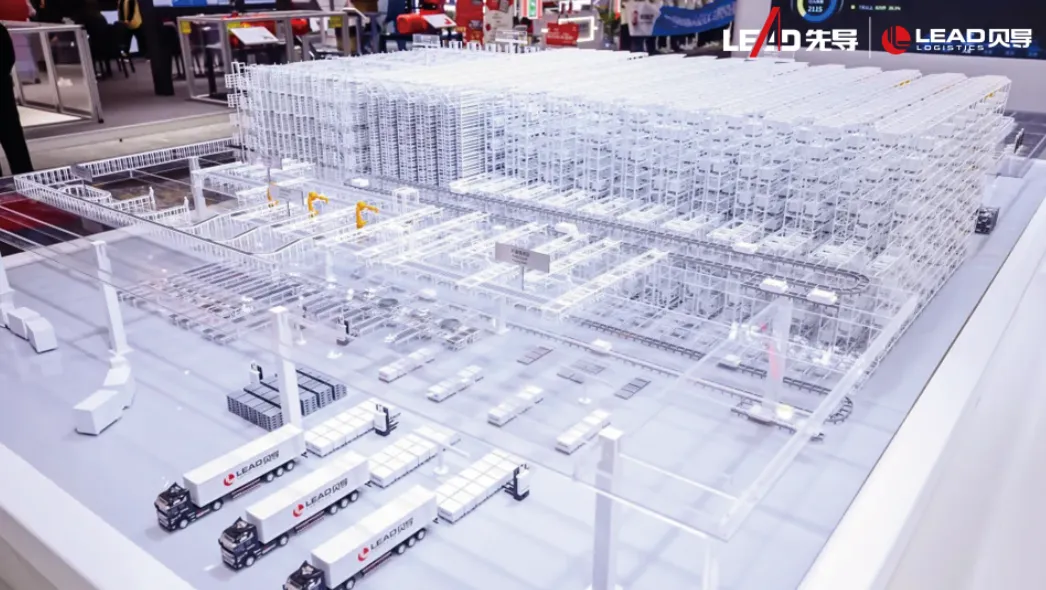

To address these industry challenges, LEAD LOGISTICS has developed a comprehensive logistics center solution for manufacturing enterprises. The system integrates flexible layouts, high-efficiency storage, goods-to-person picking, and data-driven intelligent management, delivering outstanding performance in both storage and scheduling.

The logistics center encompasses a variety of automated warehouse types – including multi-shuttle systems, miniload warehouses, pallet warehouses, and supermarket warehouse – enabling hybrid management of small-batch, multi-category items alongside large-scale materials. This allows for fast turnover and seamless order fulfillment.

A modular storage network for large, medium, and small components enables precise and adaptive scheduling. Through differentiated slot design and intelligent linkage mechanisms, LEAD has built a dynamic logistics system that allows flexible circulation of small and medium-sized parts alongside efficient storage of large components, achieving optimal balance between speed and capacity.

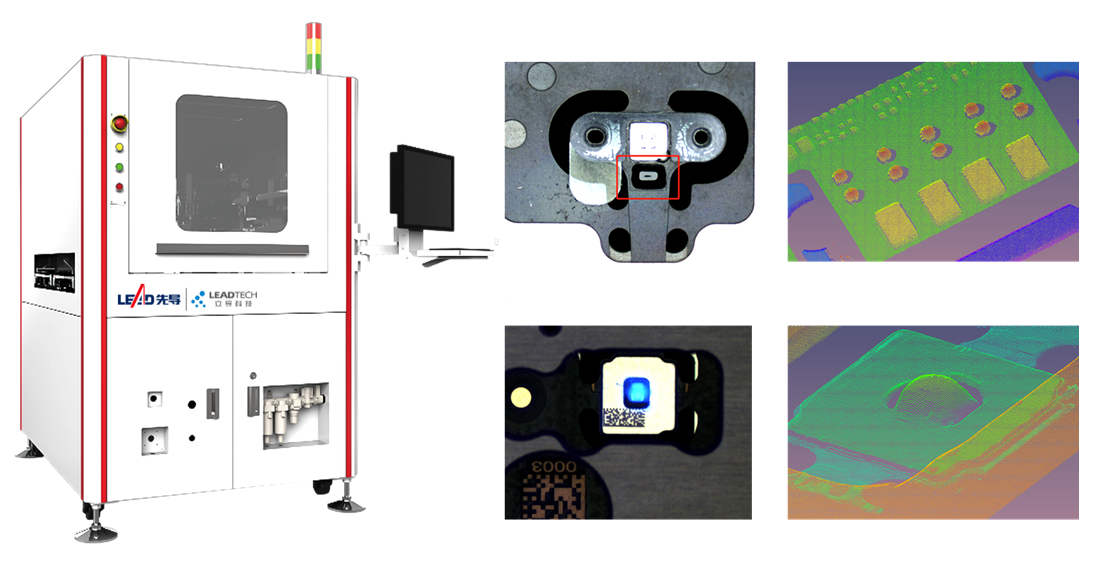

Intelligent Equipment Cluster for “Lean and Low-Manpower” Operations

An integrated cluster of intelligent storage and handling equipment – including stacker cranes, multi-layer and loop shuttles, spiral lifts, CTUs, and AGVs – operates in close coordination. Together with high-speed depalletizing and palletizing robots, as well as autonomous delivery vehicles within the industrial park, these systems enable end-to-end automation from warehousing and transport to sorting and outbound delivery.

This synergy ensures high operational efficiency across the logistics center while significantly reducing labor costs.

Digital Intelligence System: Building the Central Brain of Smart Logistics

The WMS system monitors over 400,000 SKUs in real time, triggering kitting material dispatch according to production orders. Meanwhile, the digital twin system simulates the entire logistics chain to optimize transport paths, making warehouse data both visible and precisely controllable.

The results are transformative: the system supports annual fulfillment of up to 6.5 million order lines, reduces labor costs by 74%, and cuts warehouse area by 36% across a 60,000-square-meter facility. The material kitting cycle has been shortened by more than 50%, while delivery time has dropped from two days to just half a day.

“For new energy manufacturing, logistics efficiency is the foundation of production capacity,” said the head of LEAD LOGISTICS, a subsidiary of LEAD“Our solution focuses on scenario-based adaptability — its value lies not only in the integration of equipment and systems, but also in precisely responding to the high complexity and volatility of advanced manufacturing.”

Looking ahead, Lead Logistics will continue to deepen technological innovation, building flexible logistics systems for more manufacturing enterprises and driving the industry toward a smarter, more efficient future.