Recently, CBNData (China Business Network Data Center) released the 2025 Open-Ear Headphone Category Trend Insight Report, revealing that shipments of open-ear headphones reached 24.92 million units in 2024 — a year-on-year surge of 212%. As the market expands at a rapid pace, quality and reliability have become the defining factors for high-end earphones to truly stand out. Lead Intelligent Equipment (hereafter referred to as LEAD) and its subsidiary Lead Vision Technology have long been the invisible guardians behind that quality assurance, leveraging advanced 3D + AI inspection technologies to uphold the lifeline of product excellence.

“The Intelligent Eye” Behind the Invisible Armor

What does “premium quality” truly mean for earphones? The answer lies in one critical manufacturing step — the precision conformal coating process. On the earphones’ delicate circuit boards, densely packed resistors, capacitors, and chips face constant threats from sweat, moisture, dust, and salt mist, all of which can cause short circuits, corrosion, or performance degradation. A thin yet resilient layer of conformal coating serves as an “invisible armor,” providing the essential protection that ensures high-end earphones deliver superior reliability and longevity. It is a hidden cornerstone of product value.

Recently, CBNData (China Business Network Data Center) released the 2025 Open-Ear Headphone Category Trend Insight Report, revealing that shipments of open-ear headphones reached 24.92 million units in 2024 — a year-on-year surge of 212%. As the market expands at a rapid pace, quality and reliability have become the defining factors for high-end earphones to truly stand out.

Lead Intelligent Equipment (hereafter referred to as LEAD) and its subsidiary Lead Vision Technology have long been the invisible guardians behind that quality assurance, leveraging advanced 3D + AI inspection technologies to uphold the lifeline of product excellence.

“The Intelligent Eye” Behind the Invisible Armor

What does “premium quality” truly mean for earphones? The answer lies in one critical manufacturing step — the precision conformal coating process. On the earphones’ delicate circuit boards, densely packed resistors, capacitors, and chips face constant threats from sweat, moisture, dust, and salt mist, all of which can cause short circuits, corrosion, or performance degradation.

A thin yet resilient layer of conformal coating serves as an “invisible armor,” providing the essential protection that ensures high-end earphones deliver superior reliability and longevity. It is a hidden cornerstone of product value.

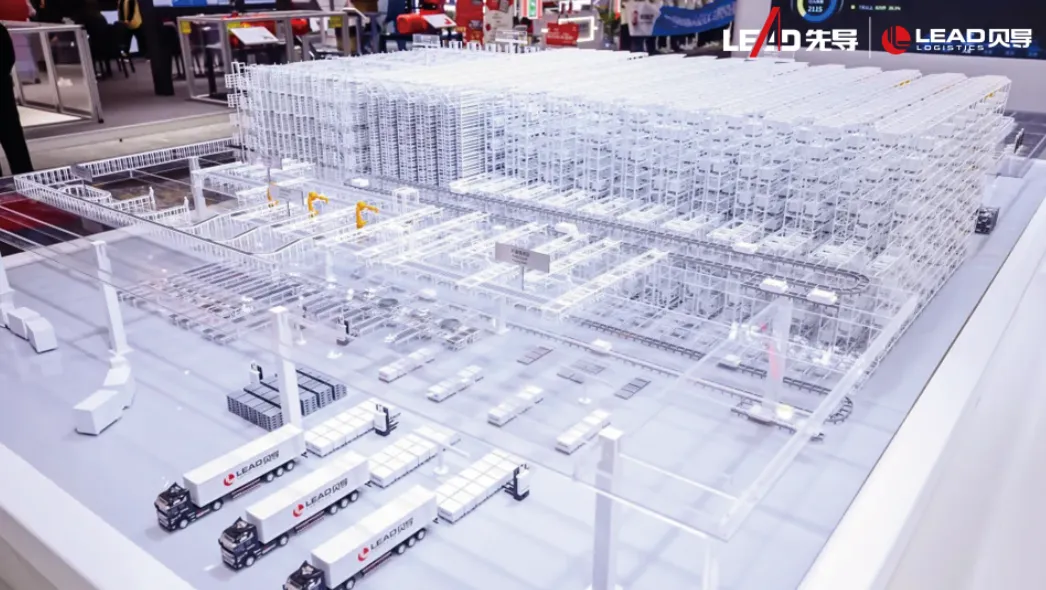

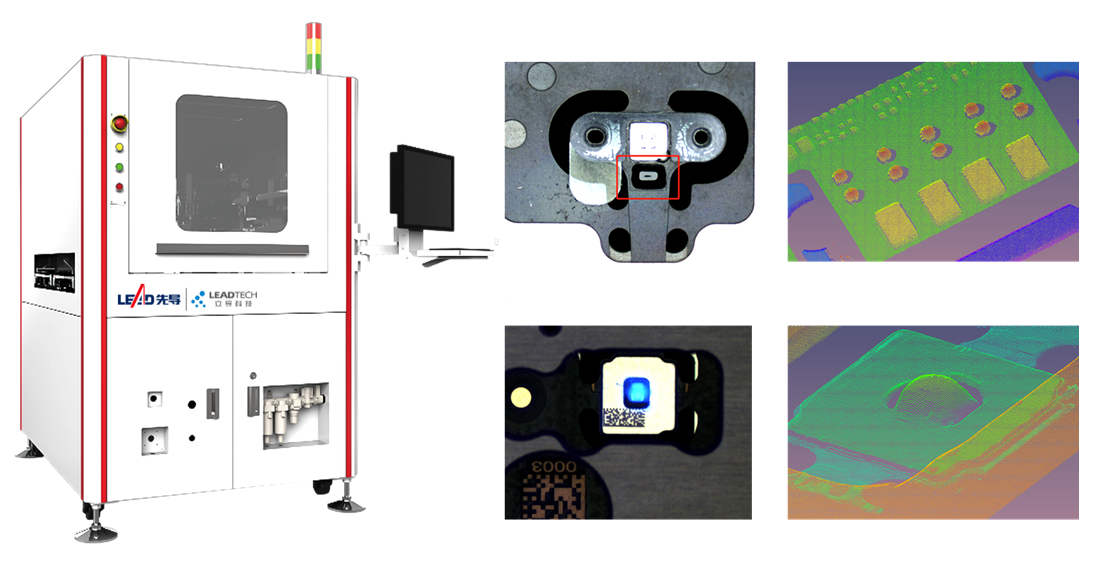

To address these common challenges, LEADTECH provides an advanced solution rooted in 3D and AI vision systems – enabling high-precision quality inspection of conformal coatings. The system combines 2D and 3D cameras to achieve comprehensive, high-speed, and ultra-accurate 3D scanning, capturing detailed geometric models of the coating layer. With 2D positioning and 3D profiling, it precisely measures multiple dimensions such as length, width, and height, achieving detection speeds up to 900 mm/s and contour extraction accuracy of 15 μm per pixel. The system performs 100% full coverage inspection, intelligently identifying defects such as bubbles, discontinuous coating, stringing, or misalignment — and automatically discharges defective products in real time.

All inspection data are uploaded to the MES system to form a comprehensive quality database. This enables customers to optimize dispensing parameters, trace quality issues accurately, and achieve continuous process improvement.

The solution also demonstrates exceptional adaptability to various adhesive types – differing in viscosity and color – while maintaining industry-leading precision, and ensures consistent coating quality under diverse process conditions, creating a solid defense line for product reliability.

Guarding Quality, Amplifying Life

In an era that celebrates individuality and diversity, young consumers are seeking more than just listening devices — they desire technological companions that reflect their energy and identity.

On this journey toward perfection, Lead Vision Technology continues to move forward as the silent “guardian of quality.” Through continuous innovation in inspection technologies, we safeguard every spark of creativity, ensuring that each idea is delivered with precision and reliability.

Here, technology and manufacturing meet — not only to redefine premium quality but also to shape the sound of our times: free, clear, and without limits.