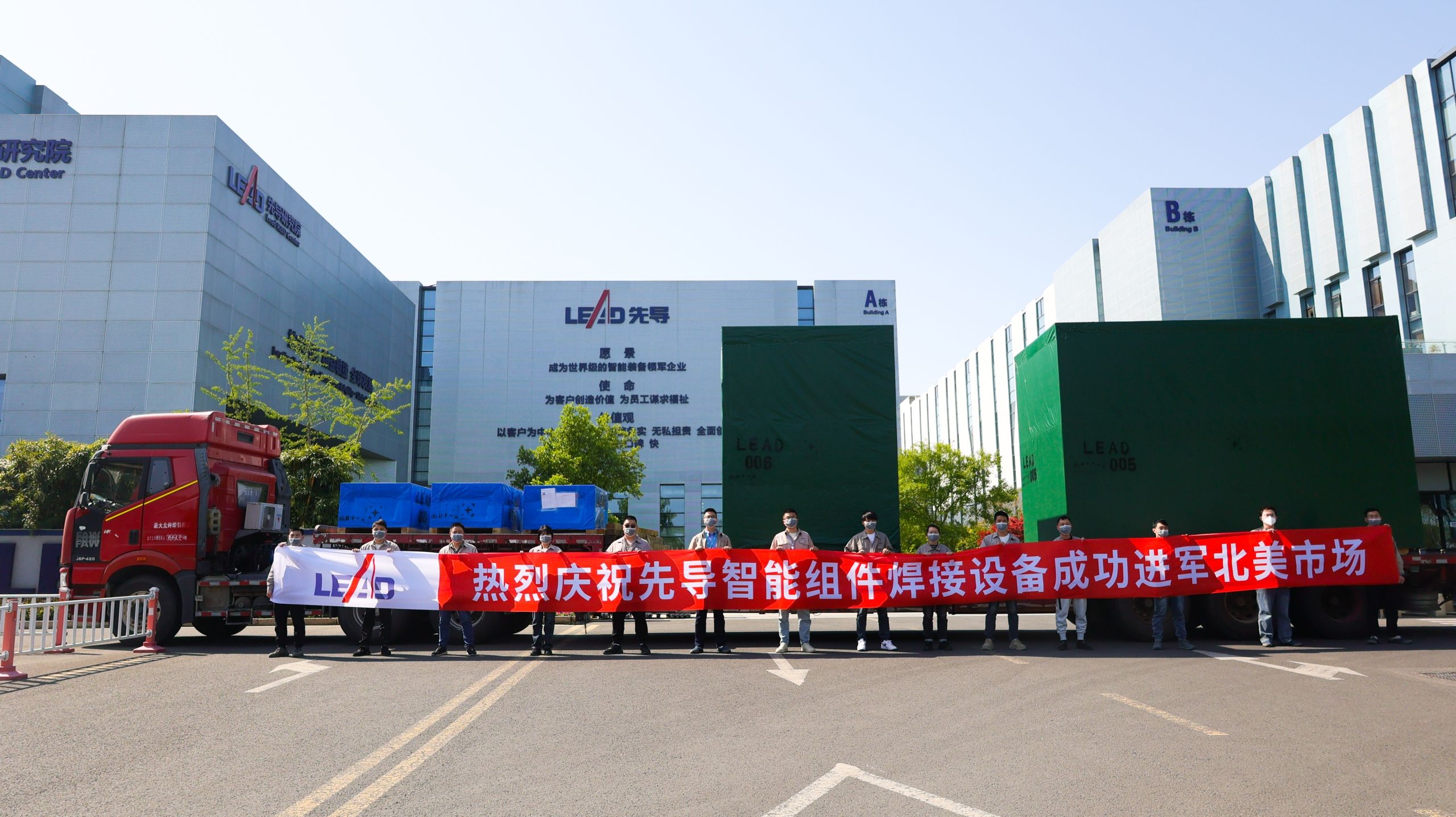

Lead Intelligent Equipment (hereinafter referred to as “LEAD”) has successfully delivered its advanced screen-printing shingling equipment to a leading global electric vehicle and clean energy company in North America. This milestone marks a significant breakthrough in LEAD’s international market expansion and highlights the company’s technical expertise and growing competitiveness in the global new energy equipment sector.

Technology-Driven: Redefining Standards for PV Module Production

The customized welding equipment is specifically engineered to meet the customer’s solar module manufacturing needs, integrating key processes such as non-destructive scribing, screen printing, and shingling. It delivers several industry-leading advantages:

High Efficiency:

Production throughput exceeds 4,000 modules per hour, significantly boosting output per unit area—meeting the demands of large-scale industrial manufacturing.

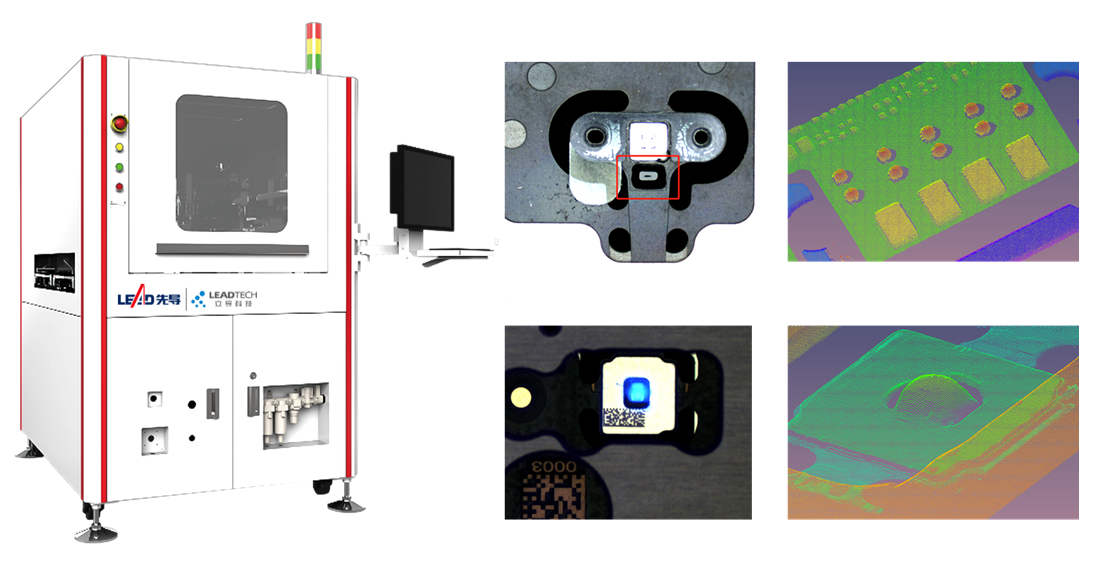

Extreme Precision:

An innovative combination of screen printing and shingling processes enables ±0.1 mm precision. With a process capability index (CPK) ≥1.33, the system far surpasses industry standards for stability and accuracy.

Exceptional Flexibility:

The equipment supports fast switching between multiple cell sizes and formats. Its modular structure allows easy adaptation to various screen-printing processes and ensures seamless compatibility with future technology iterations.

The solution adopts precision screen printing to apply conductive adhesive along the edges of each cell segment, which are then overlapped and heat-welded into strings. This overlapping layout eliminates the cell gaps commonly found in traditional modules, significantly boosting module efficiency. It provides critical support for upgrading photovoltaic product performance and delivers greater economic value to customers.

Premium Service: A New Standard for Global Delivery

Beyond the equipment’s outstanding performance, LEAD’s professionalism and service capabilities throughout the project lifecycle left a strong impression. In a letter of appreciation, the customer praised the LEAD team for its “efficient management, professional competence, and technical strength,” expressing confidence and anticipation for future collaboration.

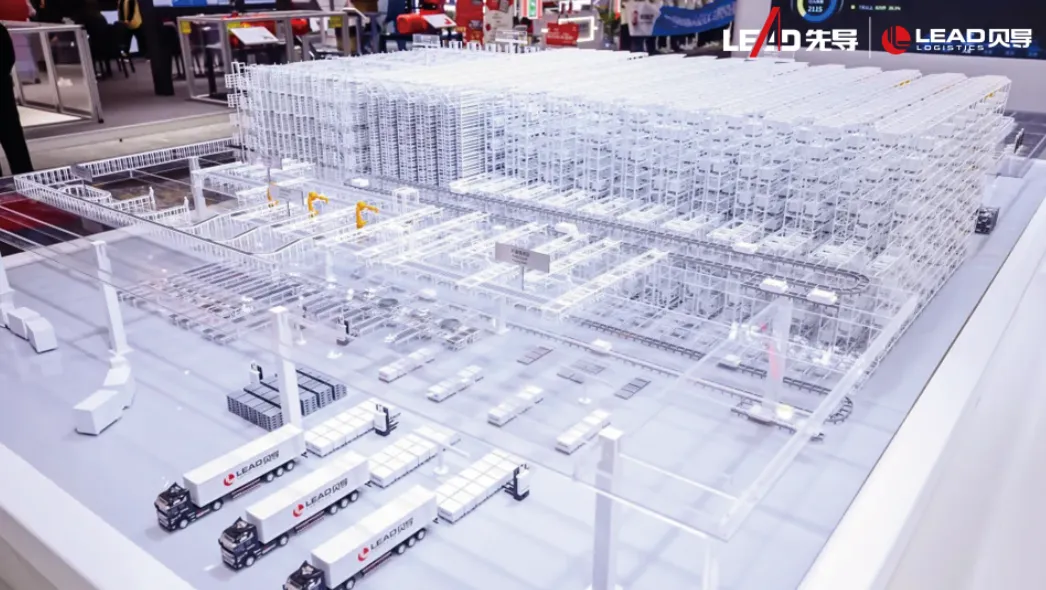

From the outset, LEAD assembled a dedicated team to manage end-to-end delivery—from early-stage design consultations and strict process controls to compliance with international certification standards, as well as onsite installation and training. Despite challenges such as evolving customer requirements, time-zone differences, and stringent certification protocols, the LEAD team demonstrated exceptional commitment and adaptability. The system was customized to the actual production environment, delivered on schedule, and seamlessly integrated into the client’s production line.

This successful partnership with a top-tier EV and clean energy enterprise not only affirms LEAD’s technological capabilities but also provides valuable experience for further expansion into the North American photovoltaic market. Looking ahead, LEAD will continue to drive innovation in smart manufacturing for the new energy sector, delivering world-class solutions and services to support the global energy transition.