Battery formation is a crucial step in manufacturing batteries for phones, laptops, and electric vehicles. It plays a key role in determining the battery’s performance and lifespan.

This step takes place near the end of the battery manufacturing process, after the electrodes, electrolyte, and casing have all been assembled. Although the battery looks complete, it’s not ready for use.

Battery formation activates the internal materials and sets the foundation for how well the battery will perform and how long it will last.

Key Terms to Understand the Battery Formation Process

Formation

The formation is the central step in this article. It’s the first time a battery is charged and discharged after being assembled. But, unlike regular charging, it’s done slowly and precisely This careful process allows the battery’s materials to stabilize and start functioning as intended.

Formation also helps create a critical protective layer inside the battery called the Solid Electrolyte Interphase (SEI), which plays a vital role in battery performance and longevity.

Solid Electrolyte Interphase (SEI)

SEI is a thin, invisible layer that forms on the surface of the battery’s anode (the negative side) during the initial charge cycles.

It’s essential for battery health—acting as a protective barrier that reduces wear and keeps the battery stable. A well-formed SEI layer leads to a longer-lasting, safer, and more reliable battery.

C-Rate

As mentioned earlier, battery formation involves charging and discharging the battery slowly for the first time. The C-rate is a key measure of how quickly this happens. It indicates the speed of charging or discharging. For example, a 1C rate means the battery is fully charged or discharged in one hour.

Degassing

During battery formation, small amounts of gas may be generated inside the cell. Degassing is the process of releasing this gas to prevent pressure buildup or swelling.

However, for certain battery types—such as prismatic cells or large-format cells—degassing isn’t always required. These batteries often undergo open formation, allowing gas bubbles to escape naturally, even within a sealed chamber.

Electrochemical Conditioning (Aging)

Battery Aging typically begins after the formation process is complete. During this stage, the battery cells undergo electrochemical conditioning for several hours or even days. This allows the SEI layer to fully stabilize and ensures the overall battery chemistry is properly set before use.

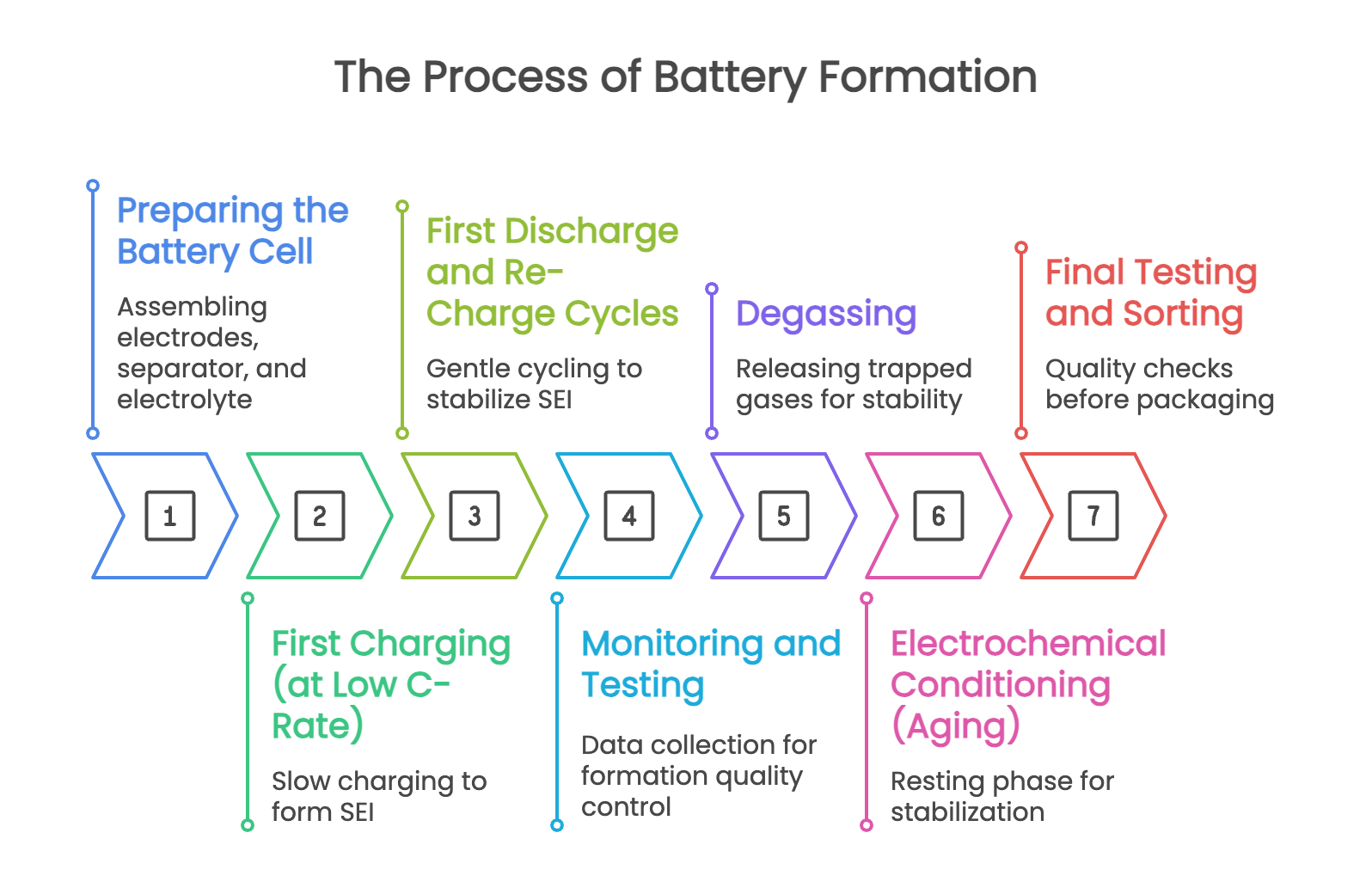

The Process of Battery Formation

As mentioned, once a battery cell is fully assembled, it still isn’t ready to power your phone, laptop, or EV. It still needs to undergo the battery formation process, a critical stage that “activates” the battery and prepares it for safe, stable, and long-lasting use.

This process involves carefully controlled charging, discharging, and rest phases. It not only forms a protective SEI layer but also helps stabilize the battery’s internal chemistry. Let’s walk through the key stages of battery formation and see how each step contributes to a high-performance, reliable battery.

Step 1: Preparing the Battery Cell

Before formation begins, all battery components—electrodes, separator, and electrolyte—are assembled into a complete cell. It resembles a finished battery but hasn’t been activated yet. The cell is then placed in a formation machine, which carefully controls the initial charging and discharging process

Step 2: First Charging (at Low C-Rate)

The battery is initially charged at a slow rate—typically 0.05C to 0.1C (over 10 to 20 hours)—at a temperature of 25–45°C. This gradual process allows a high-quality solid electrolyte interphase (SEI) to form and helps prevent damage to the internal materials.

Step 3: First Discharge and Re-Charge Cycles

After the first charge, the battery is gently discharged and then charged again—sometimes multiple times. These first cycles allow the SEI to continue forming and settling.

Step 4: Monitoring and Testing

Throughout formation, key data is collected, such as charge capacity, charging behavior, and SEI development. This monitoring helps identify early defects and ensures only high-quality cells proceed to the next stage.

Step 5: Degassing

As mentioned earlier, gas can sometimes build up inside the battery during formation. When this occurs, the cell undergoes a degassing step, where it is gently pierced in a vacuum to release trapped gases, then resealed. This process ensures the battery remains stable and safe.

Step 6: Electrochemical Conditioning (Ageing)

After formation and degassing, the battery typically enters a resting phase called aging or electrochemical conditioning. It remains idle at room temperature for several hours or days, allowing internal chemical reactions to stabilize and the SEI layer to fully mature—improving overall reliability.

Step 7: Final Testing and Sorting

After aging, the battery undergoes final testing to evaluate key parameters such as capacity, internal resistance, and voltage consistency. Only cells that meet strict quality standards proceed to packaging and integration into products.

Battery Formation Solution

As mentioned, the primary goal of battery formation is to create a stable solid electrolyte interphase (SEI) layer, which is essential for the long-term stability and performance of the cell. This stage also serves to identify weak or defective cells—such as those showing signs of overheating, abnormal voltage drops, or poor capacity.

In the broader battery supply chain, formation plays a crucial role in determining the final quality delivered to customers across industries—including electric vehicles, smartphones, and commercial or residential energy storage systems.

Because of its sensitivity and importance, battery formation requires equipment that is precise, reliable, and safe. At LEAD, we provide advanced formation solutions designed to ensure accuracy and efficiency. Our Self-Insulated Formation Integrated Machine offers intelligent control, high space efficiency, and reliable performance to support high-quality battery manufacturing.

By embedding high-temperature insulation boards, this battery formation system integrates the power cabinet with the high-temperature pressing board module, overcoming key challenges of traditional split-cabinet designs, including:

- Large equipment footprint

- Extended commissioning cycles and

- Low charge/discharge efficiency

This integrated design increases charging efficiency to 80% and discharging efficiency to 75%, while reducing the formation room area by 16%, equipment footprint by 15%, and maintenance platform area by 40%. It also employs high-precision temperature acquisition technology to ensure excellent temperature uniformity within the chambers.

The machine features a robust abnormality detection system that monitors:

- Polarity errors

- Probe and circuit contact resistance

- Environmental and channel temperatures

- Smoke presence

- Power-off protection

These advanced safety and monitoring capabilities make LEAD’s Self-Insulated Formation Integrated Machine a reliable, intelligent solution for next-generation battery formation equipment—ensuring enhanced delivery quality and operational safety.

Take a Next Step

"*" indicates required fields

Reference

- https://www.mdpi.com/2313-0105/11/4/122

- https://www.mdpi.com/2032-6653/14/4/96

- https://www.batterydesign.net/manufacture/cell-manufacturing/battery-cell-manufacturing-process/formation-aging/