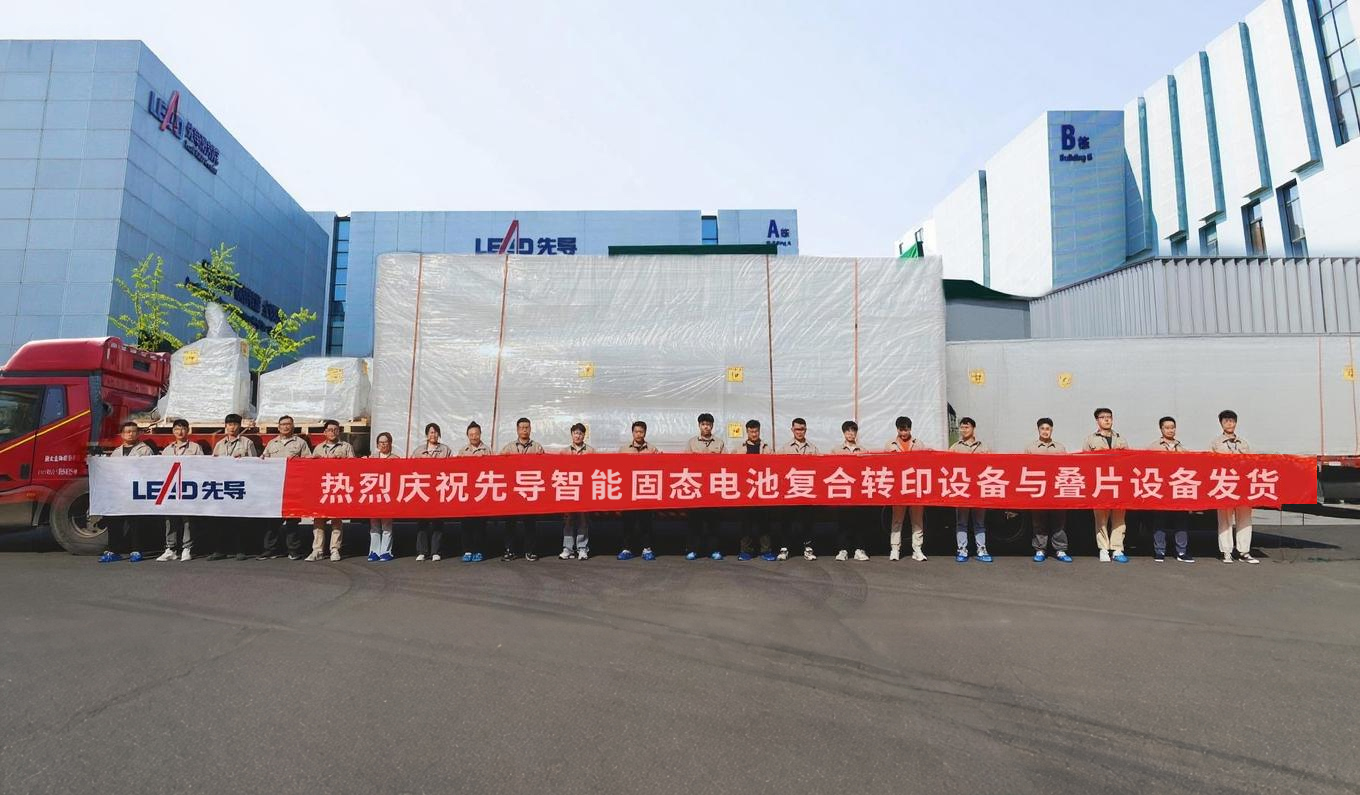

On June 20, 2025, Lead Intelligent Equipment (hereafter referred to as LEAD) announced the successful delivery of a complete perovskite solar cell production line to a leading photovoltaic manufacturer in Shanghai. This milestone represents a major breakthrough in LEAD’s advancement of high-end equipment for next-generation solar manufacturing.

The delivery not only strengthens the customer’s advanced R&D platform, but also accelerates the commercialization of perovskite cell technology through comprehensive process innovation.

Seamless End-to-End Integration and Dual Process Compatibility Drive Industrialization

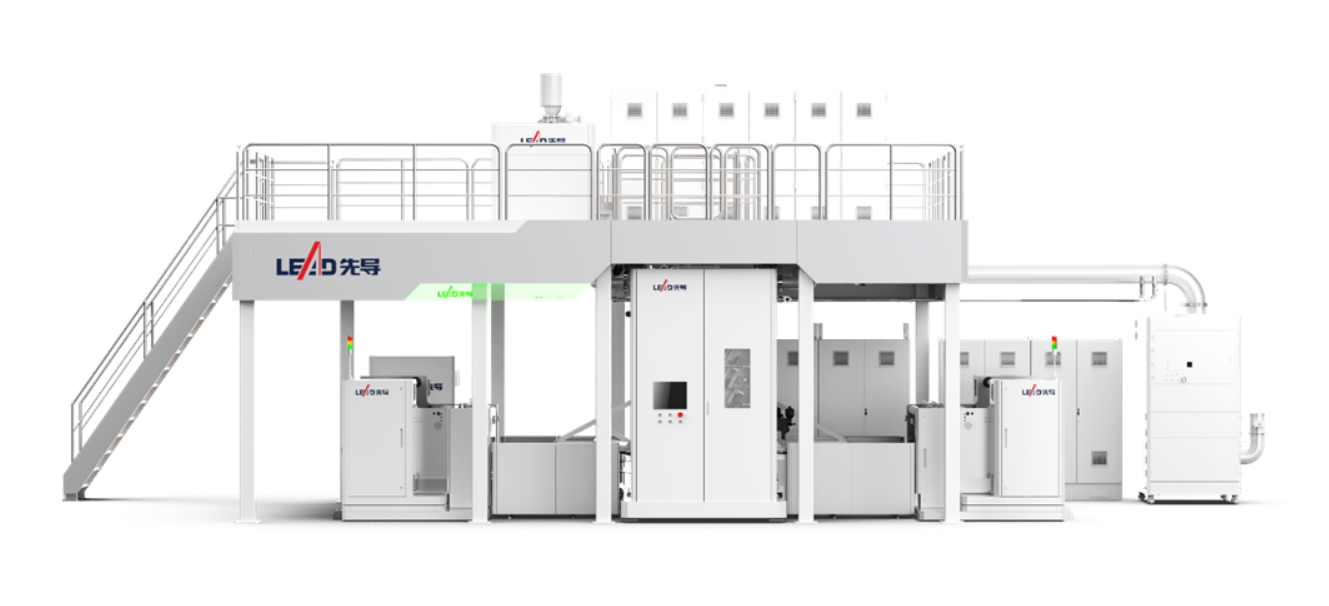

The delivered production line integrates all critical equipment required for perovskite solar cell manufacturing—from substrate cleaning, laser scribing, and coating to PVD (physical vapor deposition), ALD (atomic layer deposition), evaporation, annealing, vacuum crystallization, and module encapsulation. It supports both dry and wet processes, as well as rigid and flexible substrates, allowing customers to transition seamlessly from laboratory-scale research to full-scale production.

Notably, core modules such as the PVD system, ALD unit, evaporation chamber, laser scribing machine, and coating suite were all independently developed by LEAD. This vertical integration enables full control over key technologies, reduces delivery lead times, and enhances customer agility in the market.

Building Competitive Advantage Through Decades of Expertise

With decades of experience in lithium batteries, photovoltaics, consumer electronics, and smart automotive manufacturing, LEAD has played a key role in advancing the industrialization of perovskite technology by overcoming critical bottlenecks. The company now offers near-gigawatt-scale large-area coating equipment for mass production, along with a complete suite of coating solutions for production lines, pilot facilities, and R&D labs. Backed by over 20 years of expertise in custom equipment design, LEAD also provides comprehensive structural optimization and software customization services to help clients boost efficiency and competitiveness.

A LEAD spokesperson commented, “The commercialization of perovskite technology depends on breakthroughs in manufacturing equipment. This delivery represents a new starting point. We will continue to leverage our global network to advance perovskite manufacturing toward greater efficiency, lower costs, and smarter systems—delivering high-value ‘Made in China’ solutions to support the global energy transition.”

This milestone not only reinforces LEAD’s leadership in perovskite production equipment but also reflects the growing confidence of Chinese manufacturers in core photovoltaic technologies. As perovskite becomes increasingly integrated into mainstream solar manufacturing, LEAD will continue to drive innovation in solar equipment and help usher in a new era of transformation in the global new energy sector.